Most dredged material can be used as a resource, providing significant environmental and financial benefits and contributing to worldwide sustainability.

Placement, use or disposal

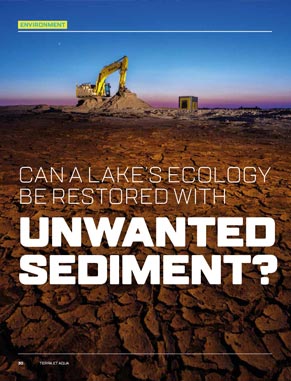

Worldwide millions of cubic metres of material are removed each year from ports, harbours and waterways in order to optimise navigation, remediation and flood management. The destination of this dredged material is often one of the greatest challenges facing a dredging project.

Over the last few decades, however, research and experience have shown that dredged material can be reused and is not inevitably a waste to be disposed. When dredged material has a purpose, it can be used, for instance, for environmental improvements, giving the material added value and creating a win-win situation.

When a use purpose is not an option, disposal alternatives must be considered and their destination on land or at sea may become controversial. Since 90 percent of dredged material is clean, use options can usually be found if all parties think about this during the planning of the project.

Finding a win-win destination

Contractors and clients now focus on finding uses for dredged material and for coordinating the supply of dredged material with a concurrent demand. This can be a win-win outcome. For instance, if a harbour is dredged, and a nearby beach needs replenishment, then the newly retrieved sediment may be suitable for beach nourishment and coastal protection.

Not all dredged material is suitable as a resource, but more often the old adage ‘seek and ye shall find’ applies. In some countries, like Japan, more than 90 percent of dredged material is ultimately put to good use.

This may require treatment of the sediments, but generally speaking, dredged material such as rock, gravel and sand, consolidated clay, silt or soft clay and a mixture of rock, can to varying degrees be used as a resource.

A variety of uses of dredged material:

- Rock may range from soft marl like sandstone and coral to hard rock like granite and basalt. Depending on size and quantity, rock can be a valuable construction material.

- Gravel and sand are perhaps the most valuable resource and are routinely used for beach nourishment, wetland restoration and coastal protection.

- Consolidated clay, if the water content is low, can be used for engineering purposes.

- Silt and soft clay usually come from maintenance dredging, are rich in nutrients and thus are good for agricultural purposes such as topsoil and for wildlife habitat development.

- Mixed materials are somewhat more restricted in use options but may still be used for fill, land improvement and topsoil.

Contaminated sediments

When dredged materials are lightly contaminated, direct use may still be an option if the environmental risks are low, taking site-specific conditions into account.

A relatively small percentage of dredged material is heavily contaminated, but even for these materials, treatment is an option. Contaminated dredged material can be separated into a usable sand portion and a contaminated silt portion in separation fields or by dewatering or in hydrocylones. The resulting contaminants then need to be reduced, removed or immobilised, after which even this dredged material can potentially be considered as a resource.

related

Articles

Study of greenhouse gas emissions during ripening of dredged marine sediment

As increasing greenhouse gas (GHG) emissions contribute to global warming, it is becoming more important to consider the carbon footprint of hydraulic engineering projects. This carbon footprint is more complex than previously thought however, as it can also include the carbon dynamics of the sediments from which projects are built. The purpose of this study was to provide a first approximation from sediment-related GHG emissions of dredged sediments. Using the case study of the clay ripening pilot project (‘Kleirijperij’) in Groningen, the Netherlands, one phase of sediment processing was examined: the ripening of dredged sediments for use as a clay material in dyke construction.

Interview – CEO of DEME Group, Luc Vandenbulcke

‘What will “sustainability” be in ten years? Our industry needs to be prepared for that.’ Luc Vandenbulcke kicked off 2019 in his new role as CEO of DEME Group. After 21 years working within the group, with 14 of those years starting up, leading and growing the group’s offshore subsidiary, he is now heading the company’s future as it navigates the evolving processes of sustainability.

How can the dredging sector join the global shift towards sustainability?

A paradigm shift is being increasingly embraced within the dredging industry. The traditional engineering approach is becoming a holistic approach in which the ecosystem is leading and values for people, profit and planet are integrated in an interdisciplinary manner.

News

New article: The Mud Motor

12 September 2019 - The Mud Motor. A beneficial use of dredged sediment to enhance salt marsh development. An innovative approach to beneficially re-use dredged sediment to enhance salt marsh development was tested by a ‘Mud Motor’. A Mud Motor is a dredged sediment disposal method in which a semi-continuous source of mud in a shallow tidal channel allows natural processes to disperse sediment to nearby mudfl